- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2023-08-04 Origin: Site

The shaft head of the SF6 compressor is sealed by a rotating magnetic fluid seal. Effectively prevent leakage of sulfur hexafluoride gas, reduce gas loss, ensure the safety and health of operators, and avoid environmental pollution by toxic substances.

What are the main functions of the SF6 compressor?

What is the application area of SF6 compressors?

What is the working principle of the SF6 compressor?

Recover SF6 gas from SF6 devices and measure the vacuum degree.

Liquefy the extracted gas for storage

SF6 plants are overhauled and air and moisture are removed

Circulate the stored SF6 gas to dry, clean, solidify and clean it. (Filtering impurities, moisture, CF4, HF, SF6 decomposition products, mineral oil, dust and flaky particles in the gas)

Vaporize the stored SF6 and send it to the SF6 equipment

Heat the gas recovery storage tank, pipeline and gas cylinder and evacuate them to 30–100 Pa.

★Inert gas such as xenon, argon or helium;

★Energy system SF6 (sulfur hexafluoride) gas;

★ Leakage of natural gas in large compression systems;

★Inert gas processing and purification of nitrogen;

★ Extract carbon dioxide from supercritical CO2 process

★ Leak gases occurring during machining such as CO carbon monoxide

The basic working principle of the SF6 compressor is the use of the refrigeration liquefaction method.

During recovery, the suction and compression properties of the compressor are used to suck the SF6 gas into the compressor at a certain pressure in the SF6 electrical plant and compress it to a higher pressure. At the same time, the SF6 gas with the higher temperature is cooled to the condensation temperature using the low evaporation temperature properties of R22 refrigerant for liquefaction and storage. In this way, it is continuously pumped to the downstream SF6 compressor until the final recovery pressure is reached.

When loading and unloading, first use the vacuum pump of the device to vacuum the SF6 electrical equipment (or steel bottle) and the connecting lines, and then directly use the pressure difference or suction of the compressor to cause a certain pressure difference for storing device in the storage container. The SF6 inside is charged into the SF6 electrical equipment until the required working pressure is reached. When the bottle needs to be filled, the liquefied SF6 is filled directly into the steel bottle using the above-mentioned properties of refrigerant R22. The cleaning function is completed synchronously when the recycling, loading and unloading functions mentioned above are completed. Two oil separators are installed in the system, each installed at the compressor outlet to effectively remove the oil contained in the SF6 gas. A drying filter is built into the system circuit to ensure the purity of SF6 entering the storage tank and effectively removing water. The filter is equipped with a heating regeneration device that can be heated and regenerated under vacuum, and the molecular sieve can be reused.

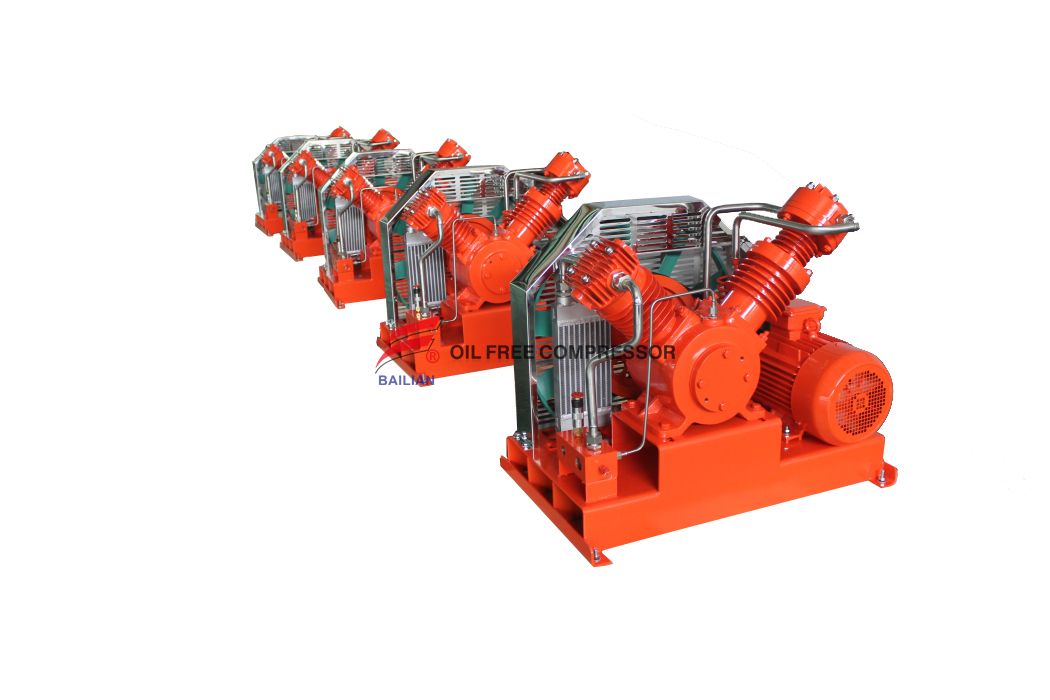

Anqing Bailian Oil Free Compressor Co., LTD. as a Chinese pioneer in SF6 compressor field can ensure the quality and after-sales service of SF6 compressor.